Phase Change Materials

Our Phase Change Materials (PCMs) are engineered for precision thermal control at defined temperatures. We utilize PCMs in our proprietary ThermaBrick® Refrigerant Bricks for optimal performance, durability, and compliance in critical cold chain applications.

What Are Phase Change Materials?

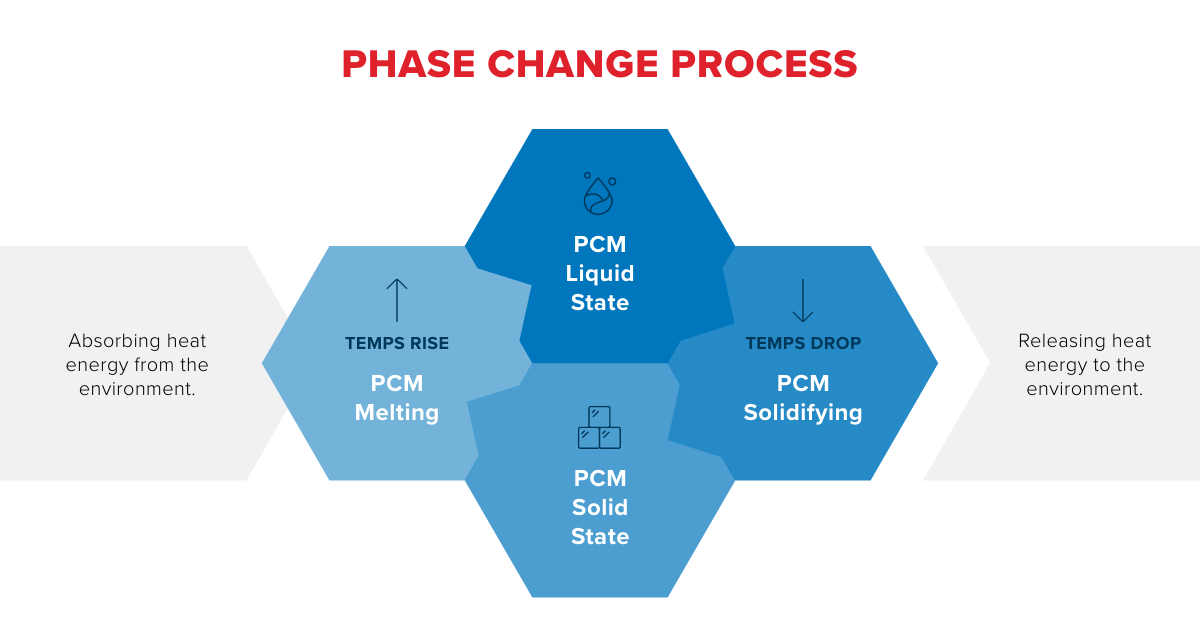

Phase Change Materials, also known as PCMs, change phase (melt/solidify) at specific temperatures, absorbing or releasing thermal energy to maintain consistent predetermined conditions. In our ThermaBrick® Refrigerant Bricks, PCMs are combined with proprietary foam to stabilize temperatures during shipping and storage.

Typical uses for ThermaBrick® Refrigerant Bricks include:

How PCMs Work in ThermaBrick® Refrigerant Bricks

Inside each ThermaBrick® Refrigerant Brick, the PCM component stores and releases energy, much like a battery, as it undergoes phase changes.

- Melting (solid to liquid): The phase change from solid to liquid on heating.

- Crystallization (solidifying): The phase change from liquid to solid on cooling.

Our integrated PCM solutions for ThermaBrick® Refrigerant Bricks deliver precise thermal control across a wide range of life science shipping needs—from frozen (below 0 °C), refrigerated (+2 °C to +8 °C), to controlled room temperature (CRT, +15 °C to +25 °C)—all within a single proven refrigerant brick system covering -21 °C to +22 °C.

Our PCM Cooling

Our ThermaBrick® Refrigerant Bricks use a variety of PCM cooling formulations, including:

Organic-based PCM products are derived from organic compounds such as paraffins and other hydrocarbons. ThermaBrick® Refrigerant Bricks made with organic based PCMs offer excellent thermal stability and are commonly used in ambient and refrigerated applications.

Key Benefits:

- High latent heat capacity

- Non-corrosive and chemically stable

- Reusable with minimal performance loss over time

Ideal For:

- Controlled room temperature shipping

- Helping to meet regulatory-compliant cold chain standards

- Cold chain logistics for medical or diagnostic samples

Formulated with natural minerals and salts, mineral-based PCM products are designed often for frozen use in the ranges of -15 to -25 °C for more rugged or high-performance environments. ThermaBrick® Refrigerant Bricks made with mineral-based PCMs offer consistent phase change behavior and are often chosen for demanding temperature ranges.

Key Benefits:

- Good thermal conductivity

- Reliable crystallization behavior

- Suitable for repeat freeze/melt cycles

Ideal For:

- Long-duration shipments

- Harsh environmental conditions

Biobased PCMs are made from renewable sources, allowing companies to prioritize sustainability. With the industry wide commitment to carbon neutrality by 2030, this makes a big leap forward while still maintaining precise temperature control across the full temperature range of -21 °C to +22 °C.

Key Benefits:

- Offers a significant reduction in the carbon footprint

- Derived from renewable sources

- Prioritizes sustainability, offering an industry advantage

- Delivers the same exceptional performance as traditional PCMs

Ideal For:

- Companies looking to reduce the carbon footprint and prioritize sustainability

PCM Temperature Ranges Available in ThermaBrick® Refrigerant Bricks

ThermaBrick® Refrigerant Bricks are engineered to protect temperature-sensitive payloads across a range of shipping conditions. Whether you need to maintain room temperature, refrigerated, or frozen environments, our cold chain solutions are tailored to your exact requirements.

Each formulation provides consistent thermal performance, reducing risk during transit and ensuring your cargo arrives at its destination in optimal condition.

Controlled Room Temperatures (CRT)

Controlled Room Temperature PCMs are ideal for applications requiring a stable room temperature environment, typically maintained between +15 °C and +25 °C. ThermaBrick® Refrigerant Bricks with CRT PCMs are commonly used in diagnostic testing, specimen transport, and medical devices that perform best under controlled room temperature conditions.

Available Specifications:

Refrigerated Temperatures

Refrigerated PCMs are formulated to maintain cold chain compliance within the 2 °C–8 °C range, often required for pharmaceuticals, vaccines, and biologics. ThermaBrick® Refrigerant Bricks with refrigerated PCMs are commonly used for pharmaceutical shipping, vaccine distribution, and biologics and clinical samples.

Available Specifications:

Frozen Temperatures

Frozen PCMs support stable low-temperature environments, which are often required for biological samples, frozen pharmaceuticals, and specialty food products. ThermaBrick® Refrigerant Bricks with frozen PCMs maintain conditions below 0 °C (and down to -21 °C), helping extend product viability and ensure thermal integrity throughout transit.

Available Specifications:

Benefits of PCM Cooling in Refrigerant Bricks

- Temperature Stability: PCM cooling in refrigerants like our ThermaBrick® Refrigerant Bricks, offer precise temperature control, maintaining a consistent temperature range throughout transit, ensuring the integrity of temperature-sensitive products.

- Maintain their Shape: Our ThermaBrick® Refrigerant Bricks do not compress or alter their shape, providing consistent cooling across the payload.

- Maximize Cargo Space: ThermaBrick® Refrigerant Bricks with PCM are customized to the size of the packaging, optimizing cargo capacity, minimizing weight, and providing consistent temperature throughout transit.

- Enhanced Product Integrity: Utilizing refrigerant bricks with cooling PCMs in cold chain shipments helps protect sensitive products from temperature fluctuations, ensuring they arrive at their destination in optimal condition, free from damage or degradation.

- Flexibility in Temperature Ranges: PCM formulations are available to accommodate a wide range of temperature requirements, from subzero and refrigerated to control room temperatures, catering to diverse cold chain needs.

- Regulatory Compliance: ThermaBrick® Refrigerant Bricks help the shipper meet regulatory standards and compliance requirements for cold chain management, including those of ISTA, US Pharmacopeia, and URAC.

Applications of Phase Change Material Products

By maintaining consistent temperatures throughout the supply chain, ThermaBrick® Refrigerant Bricks help optimize shipping efficiency and protect product integrity during shipments. Explore how our cold chain solutions meet the unique demands of the life sciences industry:

ThermaBrick® Refrigerant Bricks utilize PCMs to help protect a wide variety of pharmaceutical products, from oral medications to injectables, during storage and transit. With options across ambient, chilled, and subzero temperature ranges, ThermaBrick® Refrigerant Bricks help to ensure regulatory compliance and product stability.

Medical devices and diagnostic tools often require strict temperature control to maintain function and accuracy. ThermaBrick® Refrigerant Bricks are engineered with PCMs that safeguard sensitive medical equipment—from at-home test kits to surgical devices—against exposure to heat or cold during shipping, preserving performance and reliability.

Biotech products such as monoclonal antibodies, cell therapies, and other advanced biologics are extremely temperature-sensitive and high-value. ThermaBrick® Refrigerant Bricks utilize PCMs to maintain tight temperature control, including subzero conditions, to protect product viability throughout transit.

Blood and blood components require narrow temperature windows during collection, storage, and transport. ThermaBrick® Refrigerant Bricks with refrigerated PCM temps help maintain the critical 1–6 °C range for whole blood and red blood cells, ensuring safe delivery to hospitals, labs, and blood banks—while minimizing the risk of spoilage or rejection.

Vaccines must be stored within precise temperature ranges to remain effective—often between 2–8 °C or at ultra-cold conditions. ThermaBrick® Refrigerant Bricks are rigorously tested to support cold chain integrity for a wide variety of vaccines, from standard immunizations to temperature-sensitive mRNA-based doses.

From investigational drugs to biospecimen kits, clinical trial shipments demand consistent, validated temperature performance. ThermaBrick® Refrigerant Bricks offer stability across ambient and refrigerated conditions, supporting trial integrity, data accuracy, and regulatory compliance at every stage of distribution.

PCM Testing and Validation

At our global research labs, we provide comprehensive testing and validation services for all PCM formulations inside ThermaBrick® Refrigerant Bricks, utilizing equipment such as differential scanning calorimetry and a 3-layer Calorimeter, following ASTM standards, ISTA 7E and 7D, and RAL Quality Association PCM guidelines.

Ready to Optimize Your Cold Chain?

All Temprecision International PCM solutions are integrated into our ThermaBrick® Refrigerant Bricks — offering customized shapes with safe, multi-use, cooling capacity for temperature control applications.

Fill out the form below to request a quote, schedule a consultation, or speak with a PCM specialist.