Temprecision® Foam

Temprecision International manufactures a proprietary, high-quality, open-cell absorbent foam designed specifically for temperature control applications.

Our unique designs ensure the best total cost of ownership by maximizing efficiency and minimizing shipping container size. Temprecision International is a specialized foam manufacturer that is a committed partner with temperature control packaging companies. We ensure you meet your customers’ superior standards by developing innovative technology, customizing value-added services to minimize your materials preparation and downtime, maintaining an exceptional level of quality and technical support, and collaborating to build strategies for future growth.

Temprecision® Foam protects and maximizes your customer’s payload

How Temprecision® Foam Protects and Maximizes your Payload

- Available in any shape and size

- Absorbs a variety of phase-change materials

- Optimizes cell size

- Unique surface tension to retain fluid and minimize escape

- Better energy storage

- Prevents tumors or distortions

- Maintains stackability

- Efficiently optimizes the contents of a container with a temperature sensitive product

Temprecision® Foam is a cost-effective alternative to:

Rigid plastic bottles are costly and require an initial high carbon footprint that reduces coolant capacity and promises reusability, but often doesn’t offer a return program.

Gel packs offer cheap refrigerants, but cost significant payload capacity and leak.

Foam Properties

Temprecision® Foam is designed to maintain shape during freezing- thawing or transit and is used throughout the world by pharmaceutical packaging companies where reliability and efficiency are top priorities. Both Temprecision® Foam and ThermaBrick® Refrigerant Bricks perform up to the industry standards and commonly exceed our customer’s expectations for passive temperature control. At Temprecision International our focus is on maintaining the consistent quality of our products while delivering innovative solutions our customers use to make their packaging designs the most reliable and efficient.

Our unique solutions hold temperature more consistently than gel packs or fluid-filled plastic bottles.

Temprecision® Foam is designed to quickly and efficiently absorb a wide range of Phase Change Materials specifically designed for temperature-controlled packaging and cold chain shipping. Temprecision® Foam holds the liquid in with 95% to 99% efficiency.

Phase Change Materials known as PCM are formulated to change phase at specific temperatures, providing cold chain management at just the right temperature to protect your payload and offer consistent cooling throughout the duration of shipping. Whether you require subzero, ambient, or control room temperatures, Temprecision International has the solution for you.

We offer a complete range of Phase Change Materials to meet any need and continually innovate new solutions to match our customers’ needs.

Subzero

- PCM-21

- PCM-10

Refrigerated

- PCM0

- PCM+5

Control Room Temperature

- PCM+18

- PCM+22

Temprecision® Foam can absorb 95% to 99% of its volume. If the outside wrapping is compromised, the majority of the fluid (PCM) will be retained within the Temprecision® Foam unlike alternative product offerings making Temprecision® Foam the best choice for your customers shipping high-value cargo.

Temprecision® Foam can be cut into any shape or size for your specific application. This benefit greatly maximizes the volume of your temperature-assured cargo.

We work with world class temperature controlled packaging companies to redesign the inside of their shipping solutions to maximize the space for the temperature assured cargo.

Internal payload volume increases, while exterior volume is held constant. This allows the users a decrease in corrugate or box purchases, and, at the same time, a decrease in logistic costs associated with shipping and maintaining the temperature ranges of that cargo.

| Engineered Products | Application | Compression (PSI) | Density (PCF) | Fluid Absorption % | Size (L x W x H) |

|---|---|---|---|---|---|

| Temprecision® Foam | Foam used as a passive refrigerant | 7.0 to 12 | 1.2 to 2.0 | 95% to 99% | Any custom size up to 48” x 48” x 24” |

Temprecision® Foam has been engineered to meet our customer’s strict absorption requirements and can absorb 95% to 99% of a fluid in a matter of seconds.

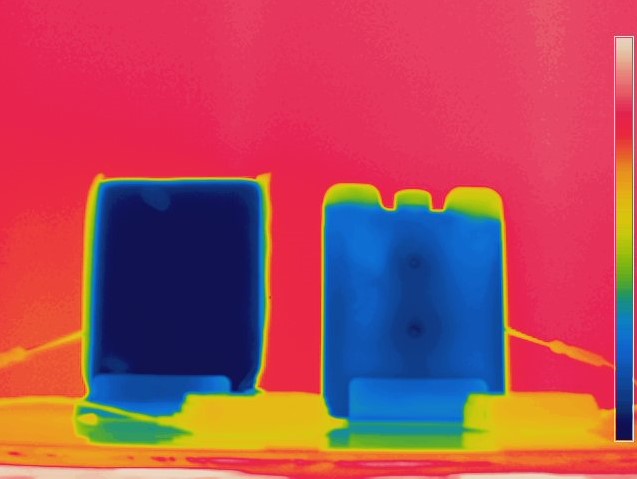

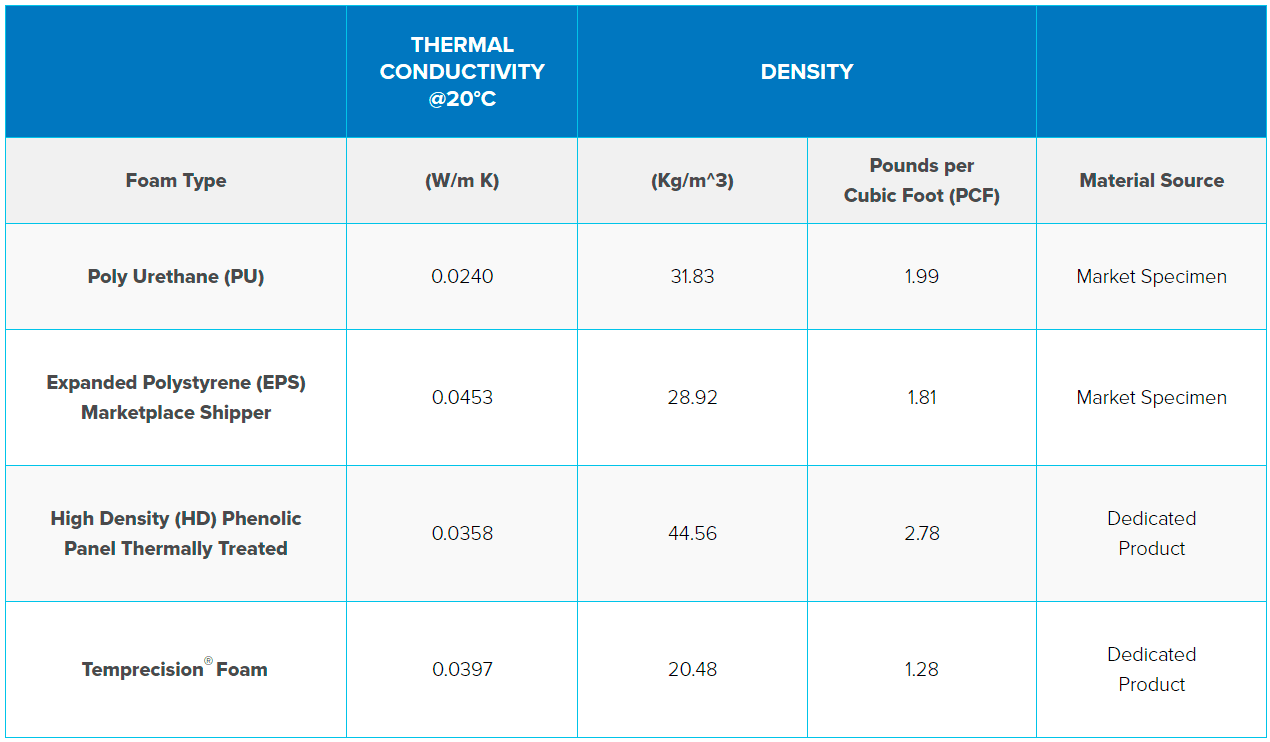

Thermal Conductivity of Temprecision® Foam is superior as compared to other materials of construction used in temperature controlled packaging designs.

*Testing Method: ASTM C518 Determining the Thermal Conductivity of a Given Material of Construction:

Temprecision® Foam is non-toxic, but not designed for consumption.