Our Advantage

ThermaBrick® Refrigerant Bricks outperform the competition in more ways than we can count, below are just a few.

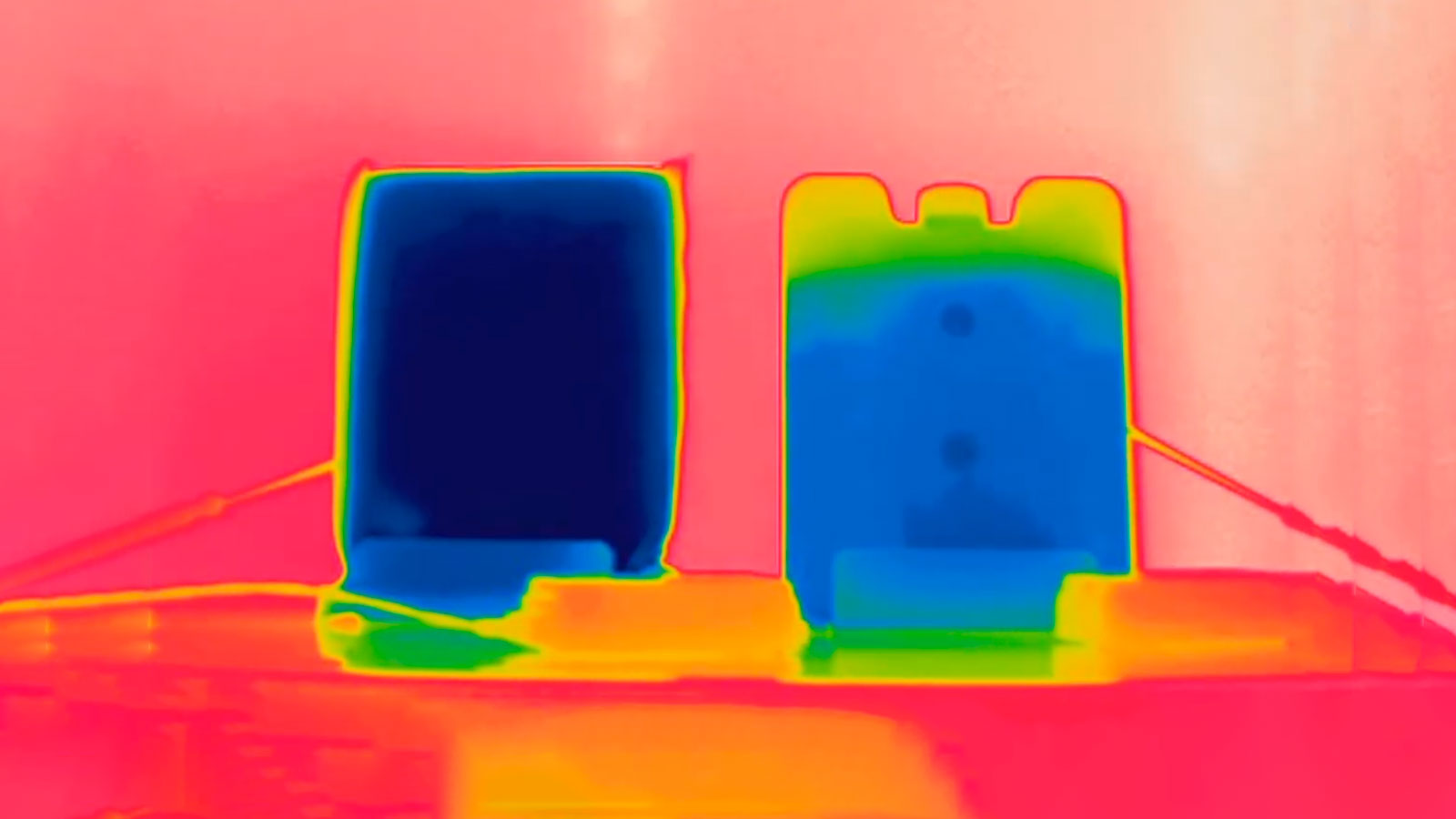

ThermaBrick® Refrigerant Bricks vs. Gel Packs

- Custom-size cooling elements are an exact match to the package design

- Fewer cooling elements provide more efficient use of storage space in the box

- Uniform temperature inside the box

- No significant liquid leakage if the cooling element is damaged

- Fewer questions and fears about the cooling liquid escape in case of damage by the customer

- Dimensionally stable during freezing process and thawing equate to higher efficiency

- Improved preconditioning storage possibilities, even in the freezer area, as refrigerants can be stacked easily

- Well documented that shape distortion occurs with gel pack refrigerants during phase change

- Shape distortion causes inconsistent heat transfer with gel packs

- Payload temperature distribution is more homogeneous with ThermaBrick® Refrigerant Bricks

- Payload reaches lower temperatures faster through conduction when ThermaBrick® Refrigerant Bricks are used

- The payload temperature is more homogeneous and lower across the payload with ThermaBrick® Refrigerant Bricks

ThermaBrick® Refrigerant Bricks vs. Dry Ice

- No hazardous goods, no labeling required, no parcel service restrictions

- No complex logistics and safety measures, no personal protective equipment

- Reduced risk for the recipients of the goods

- More precise planning, even with increased shipping volumes, reduces costs or delayed deliveries

- Efficient utilization of the storage space in the parcel

- Flexibility in packaging provides increase in the number of shipping days in a week

- Multiple uses depending on the application or through return programs

- Cooling elements that can be private labeled and branded

- Fewer complaints, better ratings by the customer

- Creates the capability to pre-pack product that would improve labor scheduling and scale your business more easily during peak periods

- Unlike dry ice, brick refrigerants present no danger to package handlers, freight companies, or consumers

- Eliminates the cost to print hazardous materials labels, manage the inventory, personal protective equipment (PPE), closed storage safety measures, costs to apply and mitigated potential fine

ThermaBrick® Refrigerant Bricks vs. Rigid Plastic Bottles

- Exact adaptation of the cooling elements to the packaging without expensive molds or tooling

- Small-quantity production is also possible

- Uniform temperature inside the shipper

- Increased control over the temperature in the box due to exact dimensioning of the cooling power.

- No over-or-under capacity, which reduces costs

- No significant fluid leakage if the cooling element is damaged

- Significantly faster freezing, especially with large quantities

- No upfront tooling costs which saves tens of thousands